Just In Time Toyota Production System

The just in time or jit method is an integral part of this strategy.

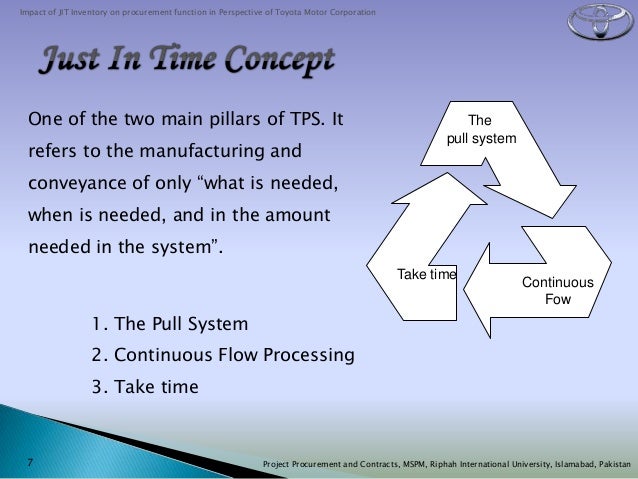

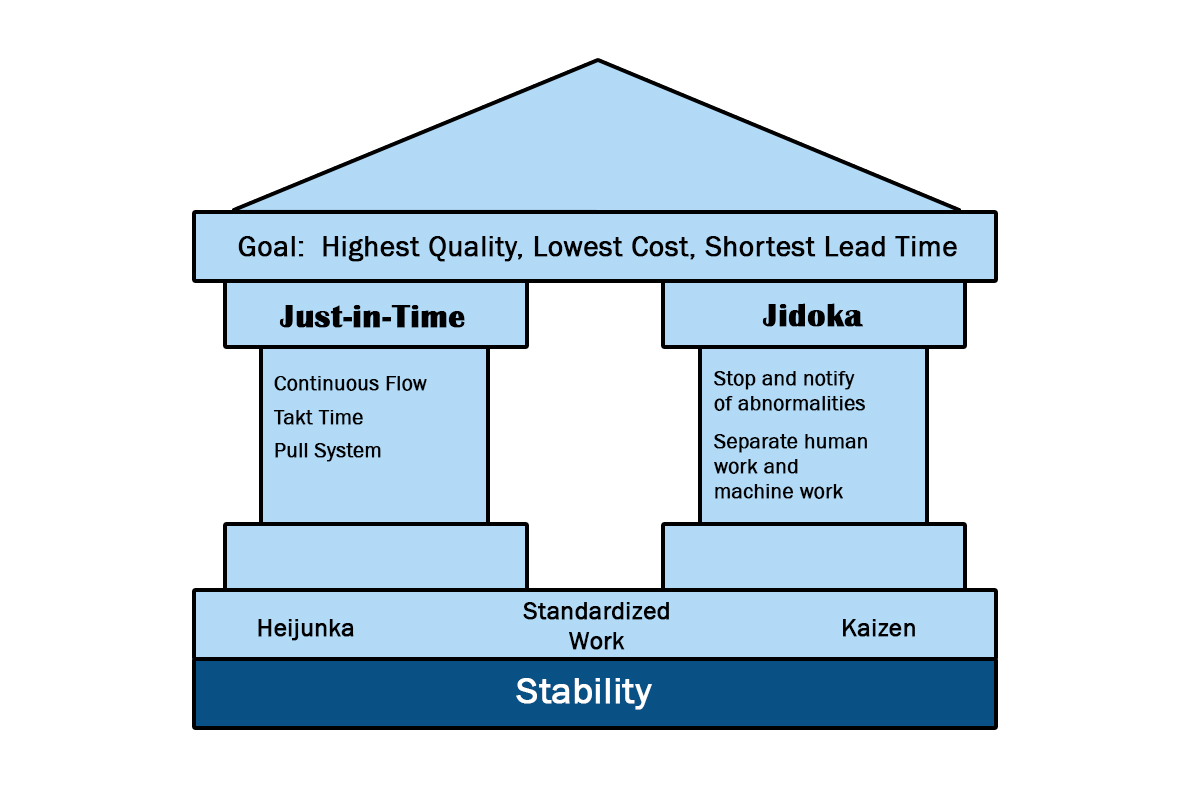

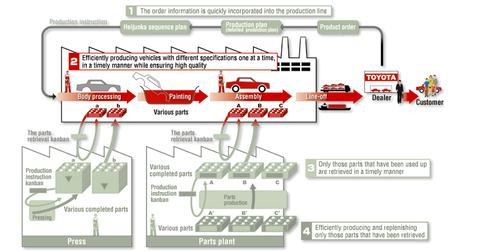

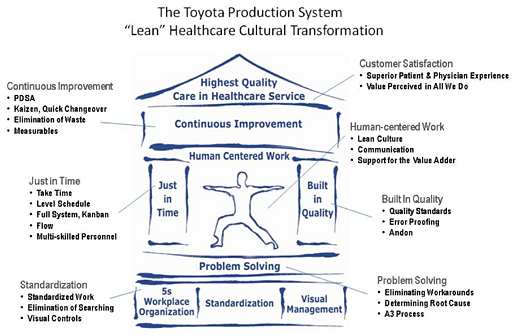

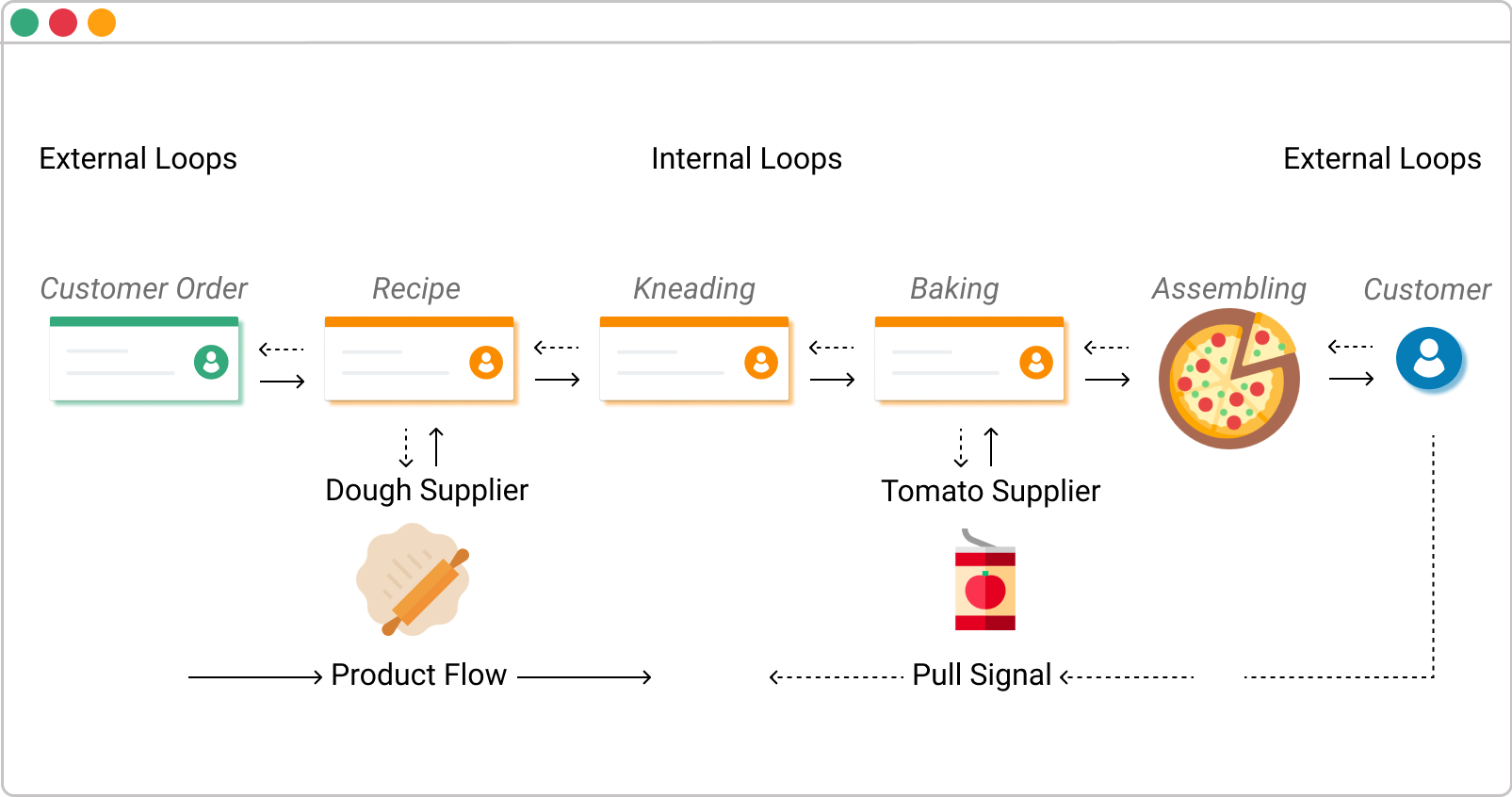

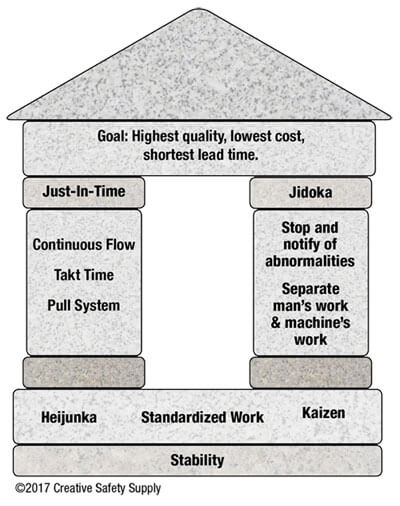

Just in time toyota production system. The system is a major precursor of the more generic lean manufacturing. Productivity improvement making only what is needed when it is needed and in the amount needed producing quality products efficiently through the complete elimination of waste inconsistencies and unreasonable requirements on the production line. The process involves ordering and receiving inventory for production and customer sales only as it is needed to produce goods and not before. A production system based on the philosophy of achieving the complete elimination of all waste in pursuit of the most efficient methods.

Just in time jit manufacturing is also known as the toyota production system. Konnyaku stone poka yoke hansei andon jidoka just in time heijunka kaizen genchi genbutsu nemawashi kanban muda muri mura genba. Its origin and development was mainly in japan largely in the 1960s and 1970s and particularly at toyota. The just in time jit inventory system is a management strategy that minimizes inventory and increases efficiency.

Just in time jit inventory management also know as lean manufacturing and sometimes referred to as the toyota production system tps is an inventory strategy that manufacturers use to increase efficiency. Whenever you buy a complex piece of equipment such as a tv or a car do you ever wonder. How exactly did they put this all together. The toyota production system or tps is one of the most notable business strategies utilized by the automaker.

This video analyzes toyo. The toyota production system tps is an integrated socio technical system developed by toyota that comprises its management philosophy and practices the tps is a management system that organizes manufacturing and logistics for the automobile manufacturer including interaction with suppliers and customers. If you ve ever studied manufacturing it s likely you will have heard of just in time production methods.

.jpg)