Gas Turbine Power Plant

A downstream turbine on the same shaft as the compressor.

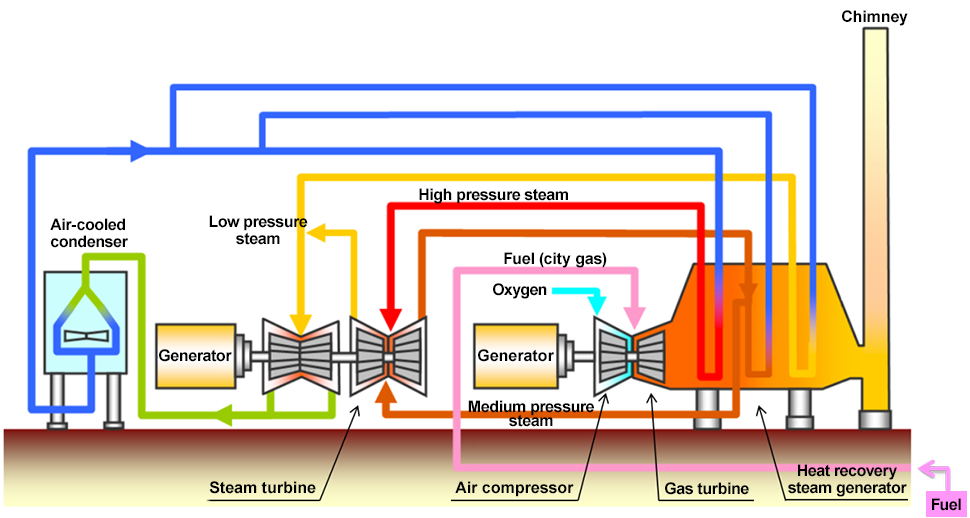

Gas turbine power plant. Hot gas spins turbine blades. Therefore air from the compressor might be used for cooling key turbine components reducing ultimate thermal efficiency. The mechanical energy created in the turbine is also utilised to run the air compressor. Major parts of a gas turbine power plant operation of a gas turbine power plant gas turbine.

Since a major portion of mechanical energy created in the turbine is utilised to run the air compressor the. A gas turbine also called a combustion turbine is a type of continuous and internal combustion engine the main elements common to all gas turbine engines are. Gas turbine working principle. Gas turbine engines derive their power from burning fuel in a combustion chamber and using the fast flowing combustion gases to drive a turbine in much the same way as the high pressure steam drives a steam turbine.

Disadvantages of gas turbine power plant. An upstream rotating gas compressor. A fourth component is often used to increase efficiency on turboprops and turbofans to convert power into mechanical or. The gas turbine compresses air and mixes it with fuel that is then burned at extremely high temperatures creating a hot gas.

Gas flowing through a typical power plant turbine can be as hot as 2300 degrees f but some of the critical metals in the turbine can withstand temperatures only as hot as 1500 to 1700 degrees f. A gas turbine power plant can more instantly be started than an equivalent steam turbine power plant. It also has multiple stages high pressure stage intermediate pressure stage and then low pressure stage.